Details

Functional Versatility Suited for Precision Engineering

Nylon rods serve as foundational components for engineers and procurement specialists focused on durable,

high-performing materials. Their adaptability across various configurations makes them an essential choice

alongside nbr material and nbr gasket solutions in sealing and mechanical assemblies. These rods fulfill

requirements for lightweight, wear-resistant stock shapes, facilitating fabrication processes with reduced

friction and extended lifespan under operational stress, thus supporting system design efficiency and

integration in component manufacturing.

Technical Attributes Driving Reliable Performance

Engineered with polyamide resins, nylon rods showcase tensile strength ranging from 70 to 120 MPa

depending on the grade, with operational temperature adaptability from -40°C to 120°C. Their inherent

low friction coefficient complements usage environments requiring compatibility with buna rubber sheets

manufacturers’ products and nbr seal material options. These rods exhibit strong resistance to oils and

fuels, alongside excellent electrical insulation. Moisture absorption characteristics and thermal expansion

rates are quantified to guide precise engineering considerations, ensuring performance consistency in

demanding applications.

Industry Use Cases Enhancing Operational Integrity

In industrial contexts such as automotive, electrical, and food processing sectors, nylon rods act as

high-strength alternatives for manufacturing gears, bushings, bearings, and conveyor components.

Their integration supports systems involving nbr gasket installations and buna rubber sheets

manufacturers’ materials by providing complementary mechanical stability and wear resistance. The

rods’ machinability and corrosion resistance promote efficiency in producing FDA-compliant instruments

and lightweight components, maximizing ROI through durable, versatile stock shapes tailored for workflow

demands in engineering and manufacturing facilities.

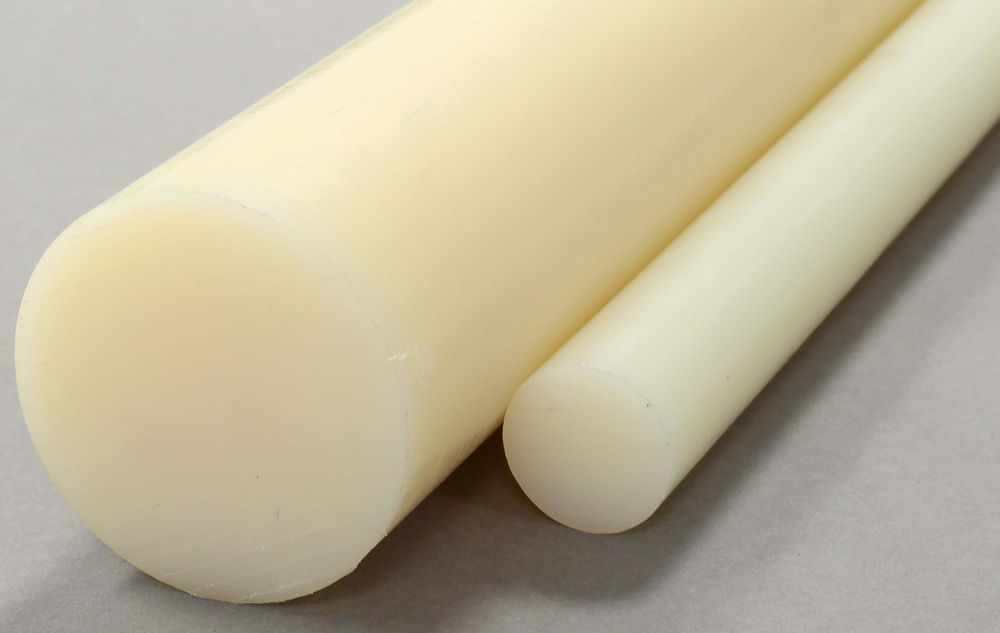

PA (NYLON) RODS

Nylon rods, or PA rods, are cylindrical stock shapes made from polyamide resins, a family of synthetic thermoplastics. Characterized by repeating amide groups in their polymer chains, they offer a blend of mechanical strength, wear resistance, and versatility. Commonly extruded or cast, these rods are utilized across industries for their durability and adaptability.

Technical Parameters:

Tensile Strength: 70-100 MPa (PA6), 80-120 MPa (PA66).

Melting Point: PA6 (~220°C), PA66 (~260°C), PA12 (~178°C).

Density: 1.12-1.15 g/cm³ (PA6/PA66), 1.01-1.02 g/cm³ (PA12).

Moisture Absorption: PA6 (3.0-3.5%), PA66 (2.5-3.0%), PA12 (1.5%).

Thermal Expansion: High, necessitating design considerations.

Dielectric Strength: ~20 kV/mm.

Product Advantages:

Lightweight: 1/7th the weight of steel.

Corrosion Resistance: Suitable for harsh environments.

Noise Reduction: Quieter than metal components.

Machinability: Easily fabricated with standard tools (sharp tools recommended).

Cost-Effective: Lower machining and maintenance costs.

Applications:

Automotive: Gears, bushings, under-hood components.

Electrical: Insulators, connectors, circuit breakers.

Industrial: Bearings, rollers, wear pads, conveyor components.

Consumer Goods: Kitchen utensils, sports equipment.

Medical: Surgical instruments (if FDA-compliant).

Food Processing: FDA-approved grades for conveyor systems.

Types:

PA6: Balanced properties, high moisture absorption.

PA66: Higher temperature resistance, stronger than PA6.

PA12: Lower moisture uptake, better chemical resistance.

Glass-Filled (e.g., PA6-GF30): Enhanced stiffness, heat resistance.

MoS2-Filled: Improved wear resistance and lubricity.

Storage:

Environment: Dry, cool, UV-protected areas.

Packaging: Sealed with desiccants to minimize moisture.

Handling: Avoid prolonged exposure to humidity; pre-dry before machining if necessary.

UV Protection: Use UV-stabilized grades for outdoor storage.

FAQ

Q: How does moisture affect nylon rods (PA rods)?

A: Moisture would cause dimensional swelling and changes.

Q: Can nylon rods be used outdoors?

A: Yes, with UV stabilizers to prevent degradation.

Q: What is the difference between PA6 rods vs. PA66 rods?

A: PA66 offers higher strength and temperature resistance; PA6 is more cost-effective.

Q: Are there any machining tips for PA rods (Nylon Rods)?

A: Basically, please kindly use sharp tools, adequate cooling, and consider annealing to relieve stress.

Q: How about the Chemical resistance of Nylon rods?

A: Nylon rods are resistant to oils and fuels; avoid strong acids/alkalis.

Q: Are Nylon rods (PA rods) recyclable?

A: Yes, through industrial recycling processes.