Details

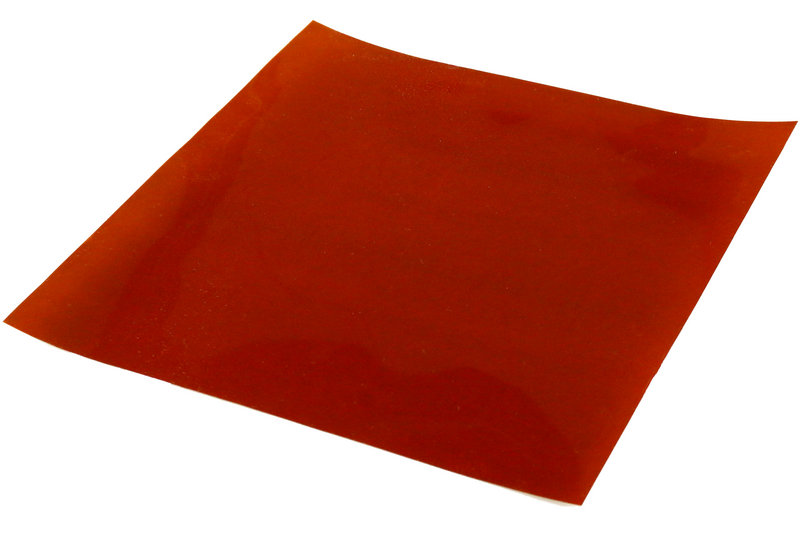

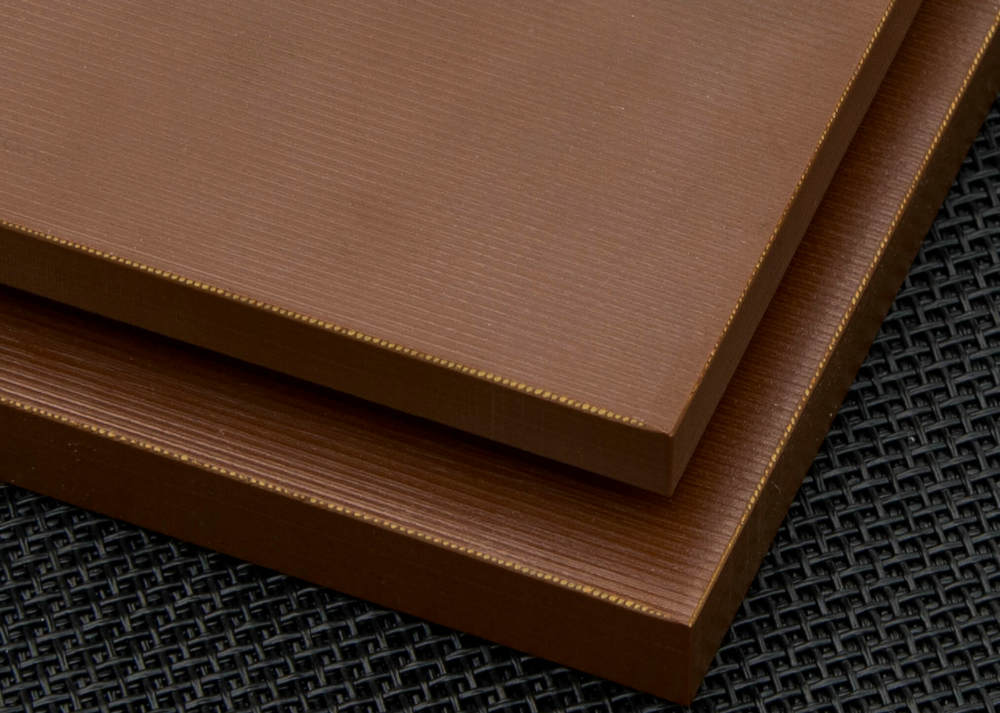

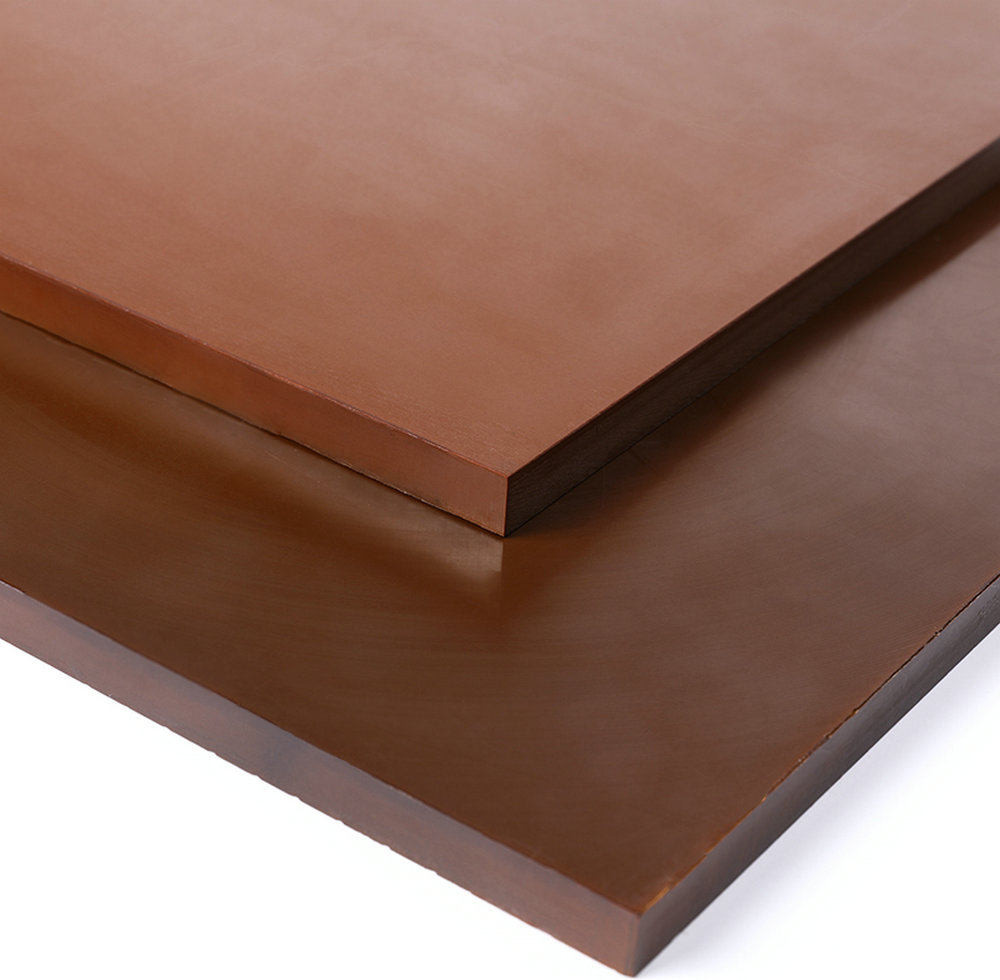

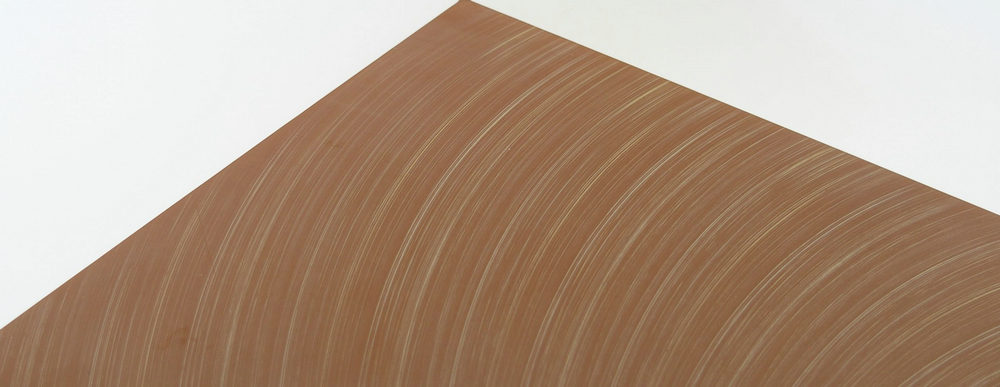

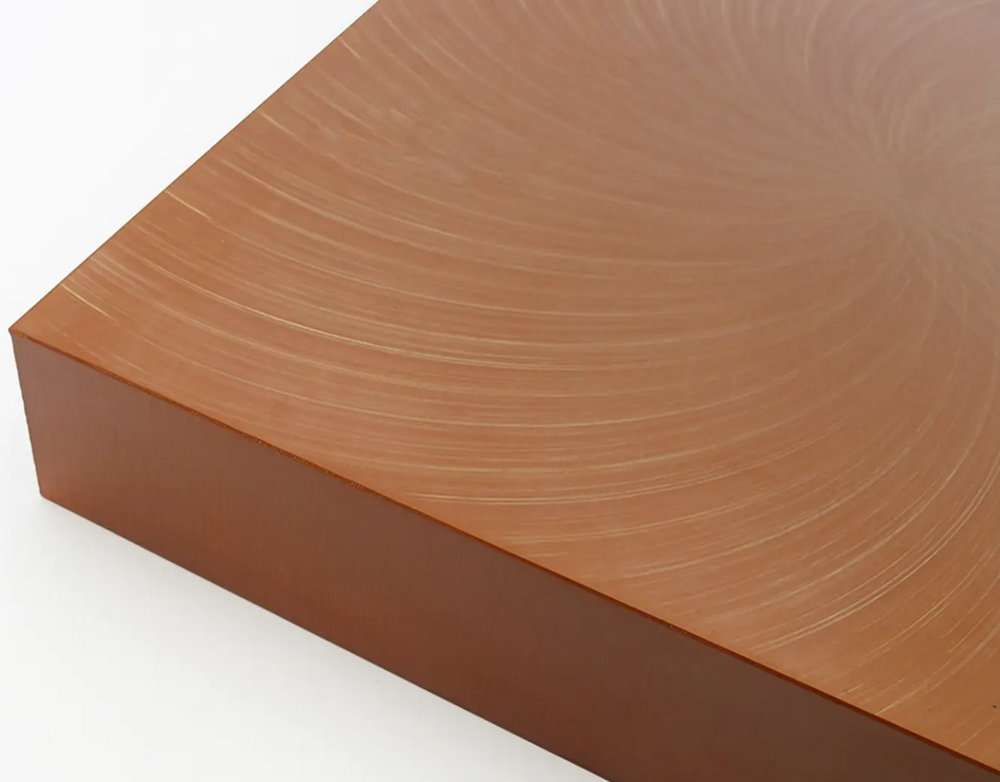

POLYIMIDE (PI) SHEETS

Polyimide Sheets (PI Sheets) are high-performance engineering plastic sheets or polymer films made from polyimide resins through processes such as polymerization, solution casting, and thermal imidization, known for their outstanding thermal stability, chemical resistance, mechanical strength, and electrical insulation properties. PI sheets maintain structural integrity in extreme environments. PI sheets are widely used in applications requiring excellent heat resistance and dimensional stability in extreme conditions, such as aerospace, electronics, and industrial applications. Polyimide Sheets are available in various thicknesses (from microns to millimeters) and forms (films, laminates, composites).

Key Features:

Thermal Stability: Operate continuously from -269°C to +300°C, with short-term peaks up to 400°C.

Chemical Resistance: Resistant to oils, solvents, acids, and fuels (exceptions include strong alkalis).

Mechanical Strength: High tensile strength (100–230 MPa) and flexibility, even at low temperatures.

Electrical Insulation: Excellent dielectric properties, even at high temperatures (dielectric strength ~200–300 V/mil; dielectric constant ~3.2 at 1 kHz).

Dimensional Stability: Low coefficient of thermal expansion (CTE: 20–50 ppm/°C).

Flame Retardancy: Naturally self-extinguishing; meets UL94 V-0 in many grades.

Radiation & UV Resistance: Withstands gamma and electron beam radiation. Suitable for aerospace and nuclear environments.

Low Outgassing: Critical for vacuum and aerospace applications.

Wear Resistance: Good tribological properties under high loads and speeds.

Types:

Type | Description |

Unfilled PI Sheets/Films | Pure PI material with no additives. Highest thermal and dielectric properties. |

Glass-Fiber Reinforced | Improved dimensional stability and rigidity. |

Carbon-Fiber Reinforced | Higher strength and improved wear resistance. |

Graphite-Filled | Enhanced lubricity and wear performance. |

Thermoplastic PI Sheets | Can be thermoformed, unlike traditional thermoset PI sheets. |

Biaxially Oriented Sheets | Thin PI films stretched in two directions for electrical insulation layers. |

Technical Parameters:

Property | Value Range | Notes |

Density | 1.42 – 1.52 g/cm³ | Depends on formulation |

Continuous Use Temperature | -269°C to +260°C | Up to 300°C for high-temp grades |

Short-term Temp Resistance | Up to 500°C | For extreme applications |

Tensile Strength | 100 – 230 MPa | High strength |

Tensile Modulus | 3.5 – 5.5 GPa |

|

Elongation at Break | 5 – 100% | Varies by grade |

Dielectric Strength | >200 kV/mm | Excellent insulation |

Surface Resistivity | >10¹⁶ Ω | Ideal for electrical uses |

Water Absorption (24h) | <0.4% | Low moisture uptake |

Flame Rating (UL94) | V-0 | Self-extinguishing |

Product Benefits:

Withstands extreme temperatures (cryogenic to high heat)

Superior heat resistance outperforming most plastics (e.g., PTFE, PEEK).

Excellent dielectric properties and insulation

Chemical and radiation resistant

Low thermal expansion (CTE)

No melting point – retains structure at high temps

Lightweight and stable with excellent wear resistance

Long service life in harsh environments

Minimal degradation under prolonged UV or gamma exposure.

Customizable via machining, laser cutting, or adhesive bonding.

Applications:

Electronics: Flexible printed circuits (FPCs), wire insulation, semiconductor wafer carriers.

Aerospace: Thermal blankets, cryogenic insulation, radiation shields.

Automotive: Engine gaskets, electric vehicle battery insulation.

Industrial: High-temperature gaskets, conveyor belts, insulating washers.

Medical: Sterilizable components, implantable device coatings.

Energy: Solar cell substrates, fuel cell membranes.

Consumer: Heat-resistant labels, 3D printer components.

Storage & Handling:

Environment: Store in cool (<30°C), dry (humidity <60%), dark conditions. Avoid UV exposure.

Handling: Store films flat or rolled (core diameter ≥75 mm) to prevent creasing. Rigid sheets should be stacked horizontally.

Contaminants: Keep away from alkalis or abrasive materials.

Shelf Life: Typically 12–24 months in original packaging.

FAQ

Q1: What is the maximum temperature PI sheets can withstand?

A: Most PI sheets withstand continuous temperatures up to 260°C and short-term peaks up to 500°C, depending on the grade.

Q2: Are polyimide sheets flame-retardant?

A: Yes. They are inherently flame-resistant and typically rated UL94 V-0.

Q3: Can PI sheets be machined or thermoformed?

A: Unfilled PI sheets can be machined using standard tools; some thermoplastic variants can be thermoformed.

Q4: Are PI sheets suitable for vacuum environments?

A: Yes. They exhibit low outgassing, making them ideal for space or vacuum chamber applications.

Q5: Do PI sheets degrade over time?

A: Polyimide sheets have exceptional aging properties and maintain performance for decades under normal use.

Q6: How do PI sheets compare to Kapton®?

A: Kapton® is a brand of polyimide film (usually thinner). PI sheets are thicker and can be mechanically machined.

Q7: Can polyimide sheets be bonded or glued?

A: Yes. Use PI-compatible adhesives or thermosetting resins for optimal bonding.

Q8: What thicknesses of polyimide films/sheets are available?

A: Typically from 0.025 mm to over 50 mm for polyimide films/sheets.

- PRE: No more

- NEXT: 130300 Polyimide Rods