Details

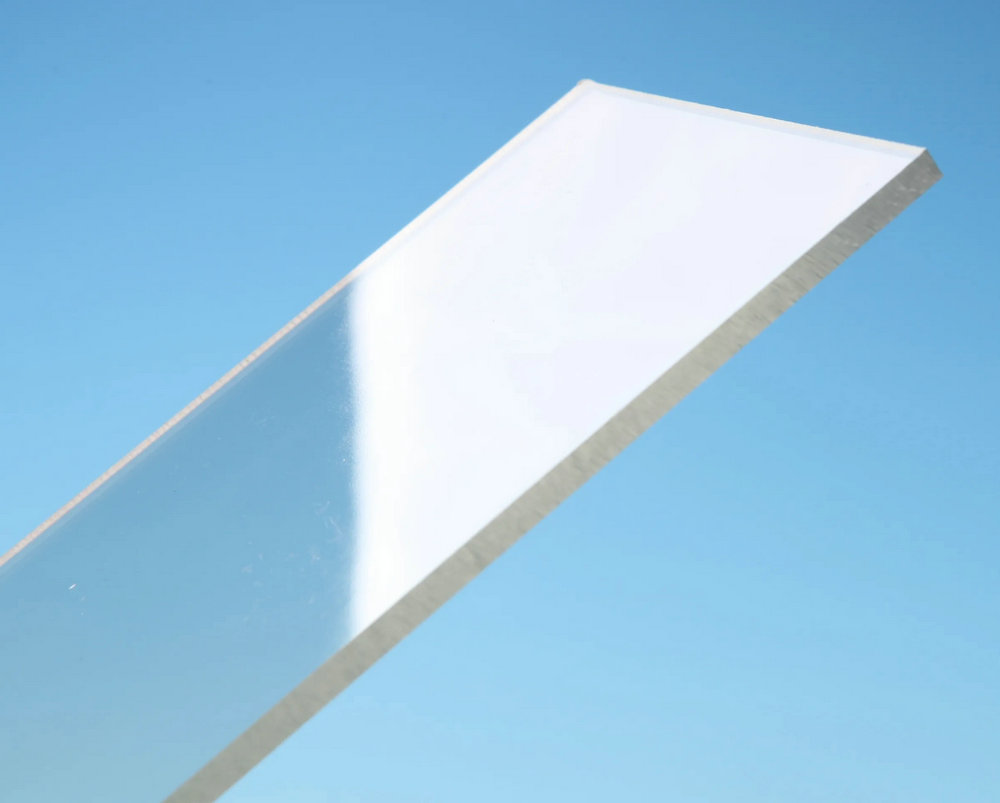

PET SHEETS

PET (Polyethylene Terephthalate) sheets are semi-rigid or flexible plastic sheets manufactured from PET polymer, a thermoplastic polyester. They are produced using processes like extrusion and calendaring, which yield flat, transparent or colored sheets with uniform thickness, exceptional clarity, and mechanical strength. PET is well known for its excellent clarity, chemical resistance, and dimensional stability. Because of these properties, PET sheets are widely used in various industries, ranging from packaging and printing to electronics and automotive components.

Polyethylene Terephthalate (PET):

Key Features:

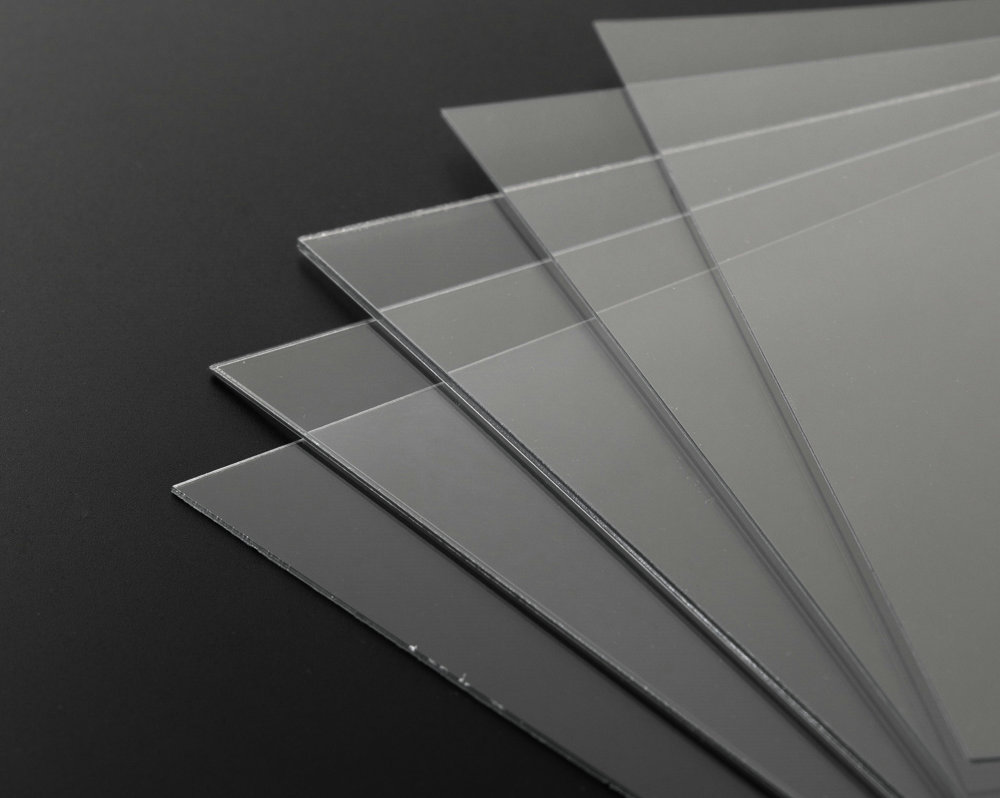

-High Transparency: PET sheets offer superior clarity and light transmission (up to 90% light transmission), making them ideal for display, packaging, and optical applications.

-Excellent Chemical Resistance: They resist a wide range of chemicals, oils, and solvents, which makes them suitable for use in harsh environments.

-Dimensional Stability: PET retains its shape and mechanical properties under varying temperatures, ensuring long-term reliability.

-Good Mechanical Strength: With high tensile (70–120 MPa) and impact strength, PET sheets can withstand physical stresses without cracking or deforming.

-Thermal Resistance: They have a relatively high melting point, between -40°C to 150°C (short-term), which supports use in applications requiring exposure to moderate temperatures.

-Lightweight: PET is a low-density material, reducing overall weight in applications like automotive and aerospace components.

-Recyclability: PET sheets are environmentally friendly, as the material can be recycled and reused in various applications.

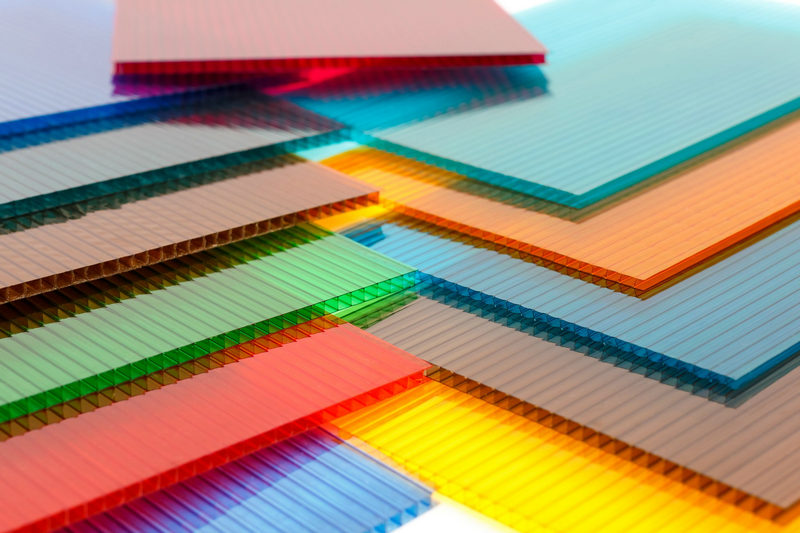

Types:

Type | Properties | Applications |

APET, Amorphous | Transparent, amorphous, rigid, glossy surface. | Blister packs, clamshells, display trays. |

CPET, Crystalline | Opaque, crystalline, heat-resistant (up to 220°C). | Microwaveable trays, oven-safe containers. |

PETG | Glycol-modified; flexible, tough, easy to thermoform. | Medical packaging, 3D printing, signage. |

rPET | Made from recycled PET; slightly reduced clarity. | Sustainable packaging, non-food containers. |

Colored PET | Dyed sheets (e.g., black, white) for UV protection or aesthetics. | Automotive interiors, decorative panels. |

Coated PET | Laminated with anti-static, anti-fog, or abrasion-resistant layers. | Electronic displays, protective covers. |

Film PET | Thin (0.1–1 mm), flexible films. | Packaging films, labels, insulation. |

Technical Parameters:

While exact parameters may vary by grade, here are some typical ranges for PET sheets:

-Density: Approximately 1.38 g/cm³.

-Tensile Strength: Common values range from 70 to 120 MPa.

-Elongation at Break: Typically 20-50%, indicating a good balance between stiffness and ductility.

-Hardness: Depending on the formulation, PET sheets can be quite hard, which aids in scratch resistance.

-Melting Point: Around 250°C (482°F), though processing temperatures are generally lower.

-Light Transmission: In amorphous PET, visible light transmission can exceed 90%.

-Coefficient of Thermal Expansion (CTE): PET sheets exhibit a low CTE, contributing to their dimensional stability under temperature fluctuations.

-Surface Quality: High-grade PET sheets offer excellent surface smoothness and can be easily printed or coated.

Product Benefits:

Versatility: PET sheets can be engineered for a variety of applications ranging from flexible packaging to rigid structural components.

Durability: Their inherent resistance to impact and chemicals makes them suitable for demanding environments.

Aesthetic Quality: The high transparency and glossy finish are ideal for consumer-facing products.

Ease of Fabrication: PET sheets can be thermoformed, cut, drilled, and printed with relative ease, facilitating custom design.

Cost-Effectiveness: Given their robust performance and recyclability, PET sheets offer an economical solution in many applications.

Environmental Sustainability: PET is one of the most recycled plastics globally, reducing its environmental footprint.

Applications:

PET sheets find application in a wide range of industries:

-Packaging:

Used for food trays, blister packs, and clear protective coverings due to their high clarity and chemical resistance.

-Printing & Graphics:

Excellent substrate for digital printing, signage, and point-of-sale displays because of its smooth surface and excellent optical properties.

-Electronics:

Utilized as insulating layers in electronic circuits, flexible printed circuits, and components in displays and lighting panels.

-Automotive & Aerospace:

Employed for interior components, instrument panels, and lightweight structural parts where durability and temperature resistance are required.

-Medical Devices:

PET sheets are used in various medical applications, including diagnostic devices and sterile packaging, due to their chemical stability and ease of sterilization.

-Industrial Applications:

They are found in protective covers, machine guards, and other equipment where high-performance plastics are needed.

Storage & Handling:

Proper storage of PET sheets is crucial to maintain their quality and performance:

-Environment:

Store in a cool, dry place away from direct sunlight. Excessive heat or prolonged exposure to UV light can cause degradation.

-Handling:

Avoid mechanical stress, scratches, and exposure to chemicals that may affect the sheet’s surface or structural integrity.

-Packaging:

Ideally, keep PET sheets in their original packaging or in protective covers to prevent dust and physical damage.

-Humidity Control:

Although PET has low moisture absorption, high humidity environments should be avoided to prevent any potential issues with surface finish or dimensional stability.

-Cleanliness:

Ensure storage areas are free from contaminants that could adhere to the surface of the sheets.

FAQ

Q1: What are the most common applications for PET sheets?

A: PET sheets are commonly used in packaging, printing, electronics, automotive interiors, and medical devices due to their transparency, strength, and chemical resistance.

Q2: How do PET sheets compare to other plastics like polycarbonate or acrylic?

A: While polycarbonate offers superior impact resistance and acrylic provides higher optical clarity, PET sheets strike a balance between durability, chemical resistance, and cost-effectiveness. They are also more environmentally friendly due to easier recyclability.

Q3: Can PET sheets be thermoformed?

A: Yes, PET sheets can be thermoformed. The process involves heating the sheets to a pliable temperature and then molding them into the desired shape. The properties of PET, such as its low CTE and high clarity, make it suitable for precision applications.

Q4: How should I clean and maintain PET sheets?

A: Use a mild detergent solution and a soft cloth to clean PET sheets. Avoid abrasive cleaners or scrubbers that can scratch the surface. For stubborn stains, isopropyl alcohol is generally safe to use.

Q5: Are PET sheets recyclable?

A: Yes, one of the key advantages of PET sheets is their recyclability. They can be processed and reformed into new products, contributing to a circular economy.

Q6: How do environmental conditions affect the performance of PET sheets?

A: PET sheets perform well under a range of temperatures and humidities, but prolonged exposure to UV light or high temperatures can lead to degradation over time. Proper storage and protective coatings can mitigate these effects.

Q7: Can PET sheets be microwaved?

A: Only CPET sheets are microwave-safe (up to 220°C). Standard APET/PETG will warp.

Q8: How does PETG differ from standard PET sheets?

A: PETG contains glycol for improved flexibility, lower processing temps, and better impact resistance.

Q9: How long do PET sheets last outdoors?

A: UV-stabilized grades last 5–10 years; standard grades degrade in 1–2 years.

Q10: What solvents can damage PET sheets?

A: Avoid acetone, ketones, and strong alkalis (e.g., NaOH).

Q11: What are the advantages of PET Sheets compared to PVC, PC, ACRYLIC and PP/PE?

A: Please refer to the info below:

vs. PVC: Higher clarity, better environmental profile (non-chlorinated).

vs. Polycarbonate: Lower cost, better chemical resistance.

vs. Acrylic (PMMA): Superior tensile strength and moisture resistance.

vs. PP/PE: Better rigidity and dimensional stability.

- PRE: No more

- NEXT: 100300 PET Rods